The steel casting field is constantly evolving, pushed because of the need for bigger precision, enhanced good quality, and diminished defects. In this particular landscape, the pressure casting machine plays a vital role. However, for quite possibly the most demanding programs, a specialized type of casting machine is necessary: the vacuum force casting equipment. This article explores the exceptional advantages of these devices, focusing on how they greatly enhance the precision and high quality of steel casting, especially for treasured metals like gold and platinum.

Table of contents:

The Advantages of making use of Vacuum Pressure Casting equipment for prime-excellent outcomes

How Vacuum Pressure Casting boosts the Accuracy of Gold, Platinum, together with other Metals

Why Vacuum tension Casting is important for superior-Precision Industries

The Advantages of making use of Vacuum strain Casting Machines for prime-high quality benefits

Vacuum tension casting devices offer you an important step forward in comparison to standard casting procedures. The core gain lies from the elimination of get more info air pockets and gasoline porosity within the casting. By doing the casting method beneath a vacuum, the molten steel is permitted to move additional freely and completely fill the mold cavity. This brings about denser, much better castings with fewer inside defects. Also, the application of pressure throughout the solidification section really helps to more consolidate the metallic, reducing shrinkage and enhancing the overall excellent. This makes vacuum stress casting perfect for producing intricate and complicated patterns where even the smallest imperfections can compromise the features or aesthetic appeal of the ultimate product.

How Vacuum strain Casting Enhances the precision of Gold, Platinum, and various Metals

The superior value and one of a kind Homes of important metals like gold and platinum necessitate Fantastic casting precision. Vacuum gold casting equipment technological know-how is specially made to meet up with these demanding demands. The vacuum atmosphere not merely prevents oxidation of your molten metal and also makes sure a clean and regular casting approach. This is especially critical for gold, which can easily tarnish or build surface defects if exposed to air for the duration of casting. What's more, the managed strain used in the course of solidification encourages uniform grain structure and minimizes the chance of cracking or distortion. This ends in castings which have been dimensionally correct, have exceptional surface finish, and keep the desired mechanical Qualities.

Why Vacuum force Casting is important for large-Precision Industries

High-precision industries, including aerospace, health-related system producing, and large-stop jewelry creation, rely upon vacuum pressure casting to attain the stringent good quality criteria essential for his or her apps. The ability to deliver castings with restricted tolerances, minimal defects, and regular product Houses is paramount in these sectors. as an example, inside the aerospace business, vacuum force Forged factors are Utilized in crucial motor sections wherever reliability and functionality are non-negotiable. Similarly, in health care unit manufacturing, vacuum stress casting guarantees the biocompatibility and structural integrity of implants. The benefits prolong to jewellery creating in addition, exactly where intricate models and flawless finishes are essential for creating substantial-price items. in the long run, vacuum strain casting presents the necessary Command and precision to fulfill the demanding prerequisites of such industries. As evidenced by products and solutions much like the TAKJ-VC-W readily available at https://taeantech.com/products/takj-vc-w, these devices are specially created to cater on the precision required by vacuum strain casting procedures.

In summary, vacuum tension casting equipment are indispensable resources for accomplishing superior precision and outstanding top quality in metal casting. The mix of vacuum setting and managed force removes frequent casting defects, improves content properties, and makes sure dimensional accuracy. For industries demanding the highest levels of general performance and reliability, buying vacuum stress casting technological know-how is not only a option but a requirement. look at the specific requirements of one's application and take a look at the assorted vacuum force casting answers available to unlock new alternatives in metal casting and elevate the quality of your closing merchandise.

Katie Holmes Then & Now!

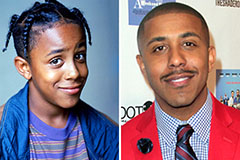

Katie Holmes Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!